2. Gold-tin hard solder technology

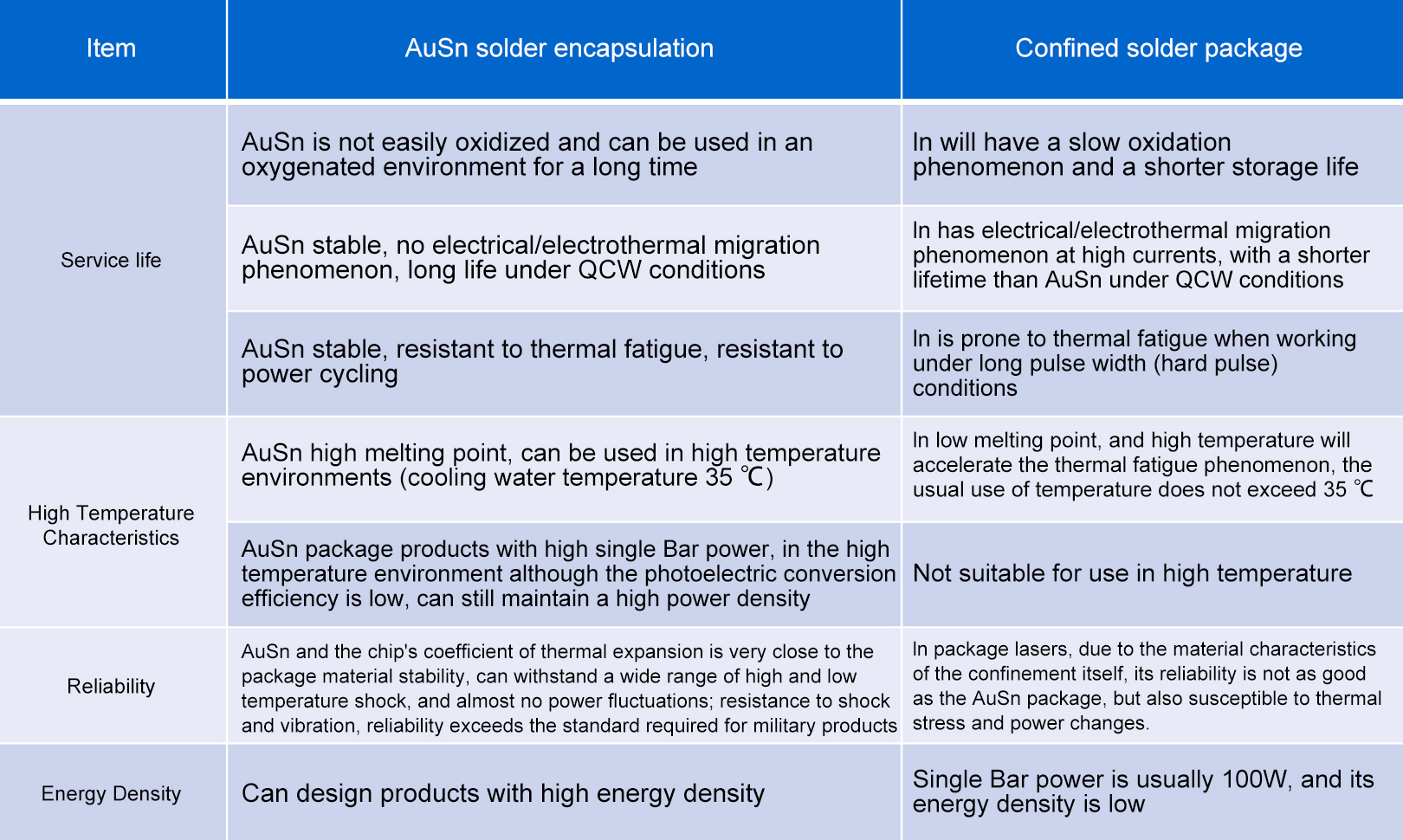

Adopting gold-tin hard solder technology, which has the characteristics of working under more severe conditions and higher reliability than indium-encapsulated products;

High duty cycle, high-temperature resistance, long life, 2 years / unlimited light / free replacement.

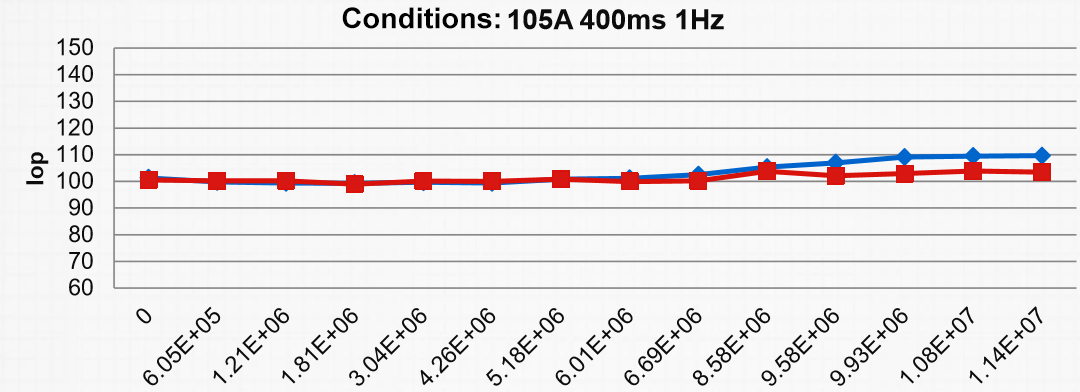

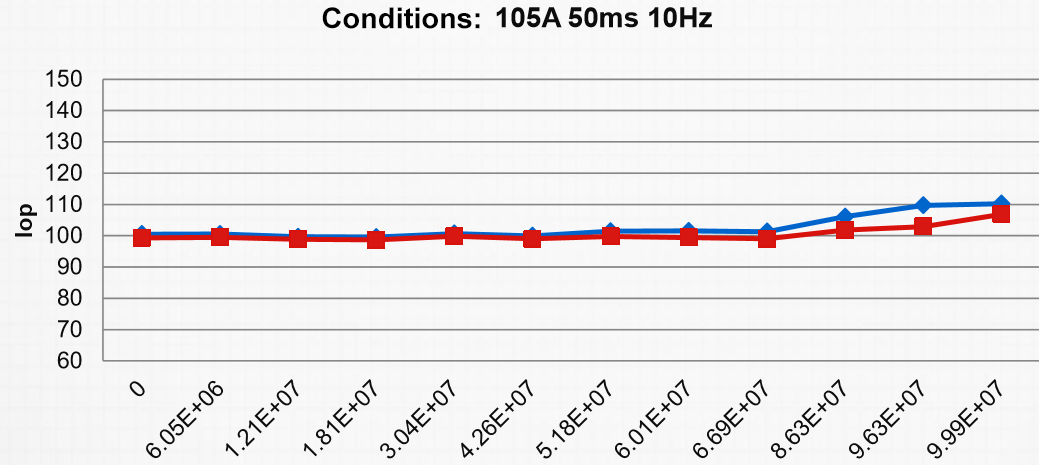

3. More than 100 million times luminous under high occupancy

More than 100 million luminescence in the case of high-frequency luminescence

4. Thermal management and thermal stress techniques

These two mainly detect the reliability of the laser and design the most reasonable laser structure.

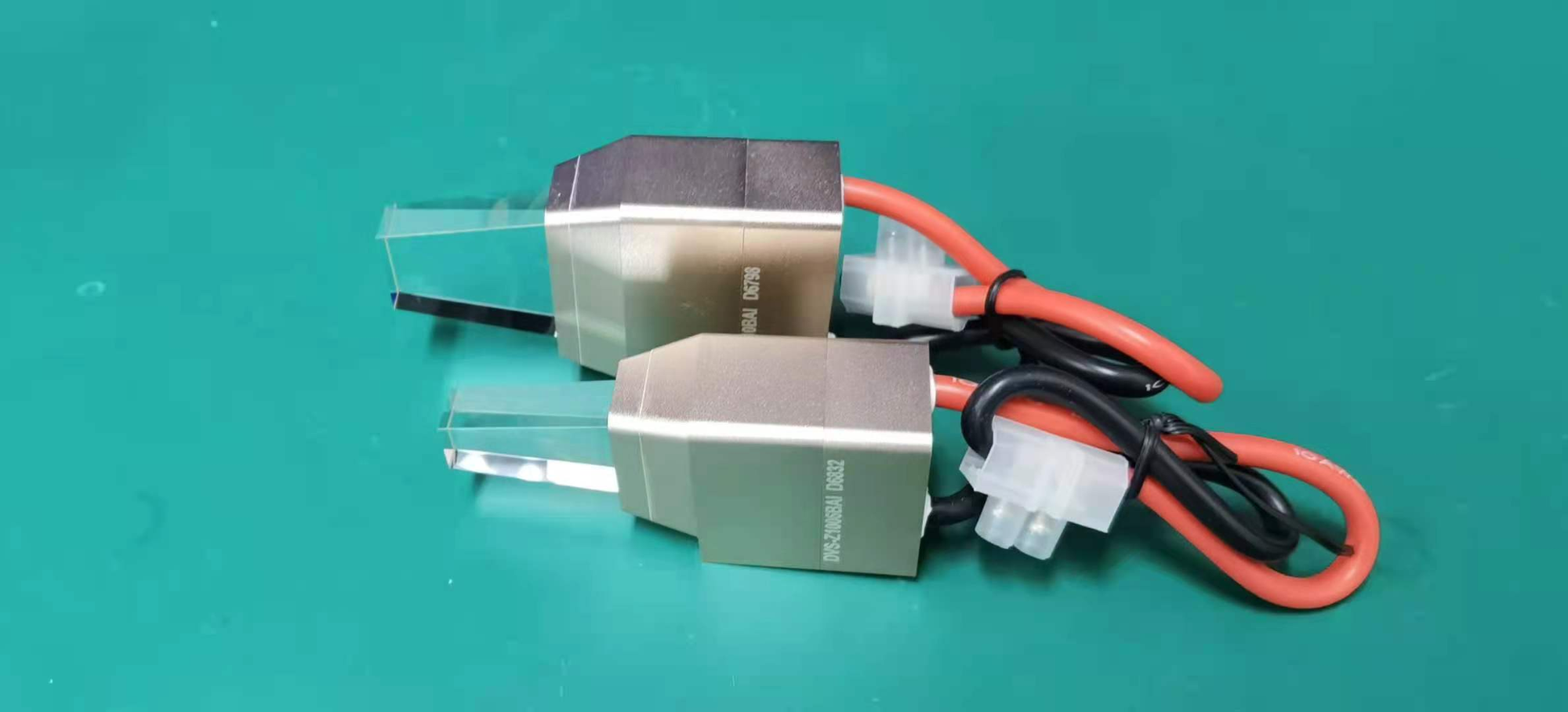

5. Light cone integrated machine technology

Mainly can reduce the laser dispersion angle, so that the energy is more concentrated and more uniform while reducing the loss of energy, and the laser will not burn because of condensation (the early laser and light cone are separated, the laser is water-cooled and the outside world has a temperature difference, if the humidity is high on the laser will have condensation, condensation flow into the laser light-emitting surface will burn, the integrated light cone will not have this problem).

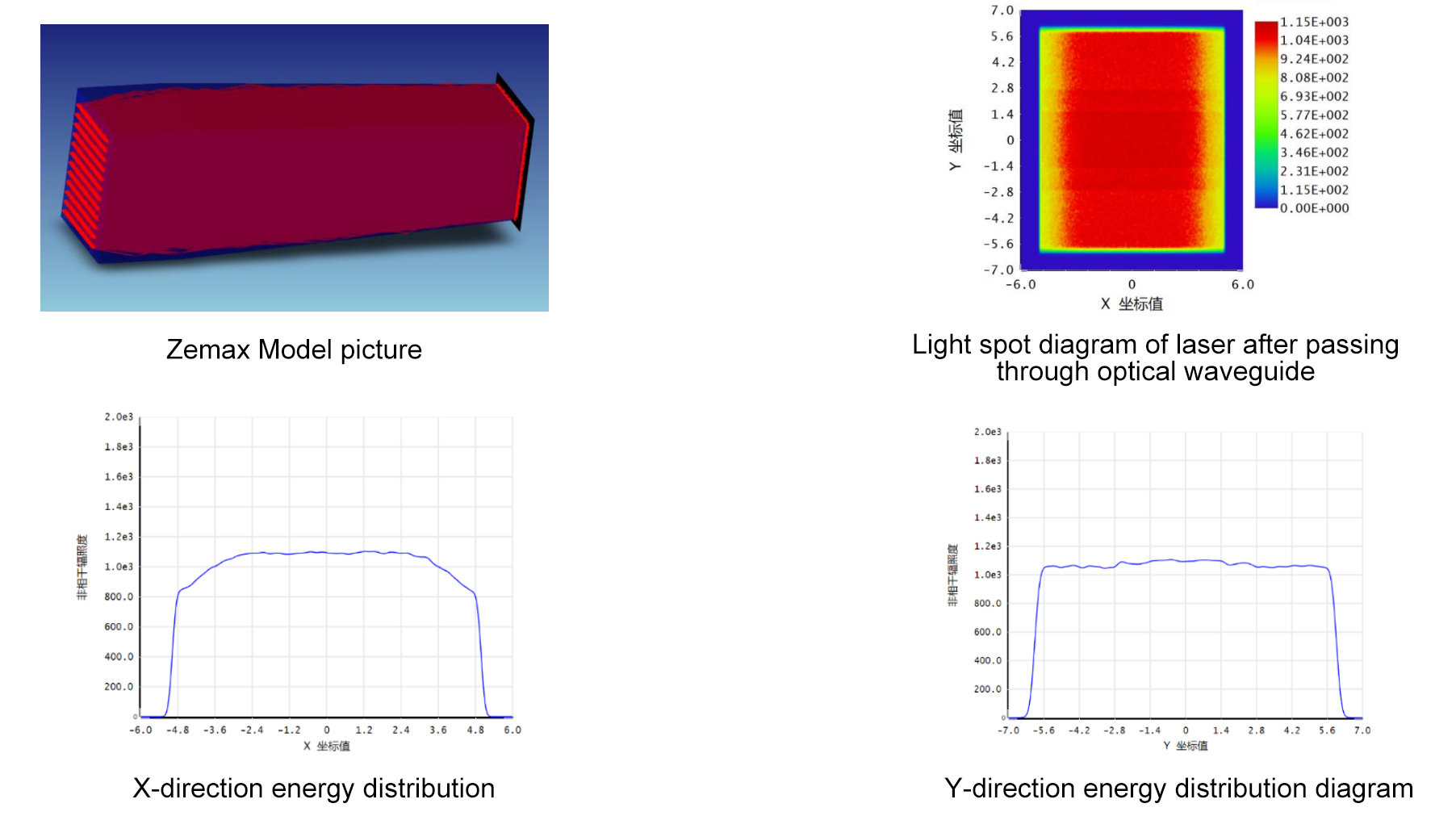

6. Light spot homogenization technology

High-end 1200w is a torchlight integrated light cone laser, the optical part is LIMO design uniformity can reach more than 90%, the other products are basically 85% or more, the higher the uniformity, the better the treatment effect, the better the comfort, fiber optic can generally be more than 95% at the same time the price is more expensive (low-end are split laser, the cost is low, but the energy loss too much more).

7. Nitrogen sealing, anti-oxidation, and waterproof

Mainly or extend the life of the laser, while preventing the laser into the water.

8. Conduction cooling technology

Different from the macro channel (waterway thick not easy to block, but the general effect of heat dissipation, low energy, low duty cycle) and microchannel (waterway is very thin, but can fully dissipate heat, energy use is very high, the duty cycle is also high, but very test the performance of the whole cooling system, high cost clogging on the burn), conduction cooling using patented technology, combined with a wider waterway design, so that the laser heat dissipation more fully.

Accessories section

1.4 Spectrum laser protection glasses

Protection range: 740 - 1100nm OD 5+ / 780 - 1070nm OD7+

Light transmission rate: 40%

Typical laser wavelengths: 755nm, 808nm, 940nm, 1064nm

Application areas: violet emerald, semiconductor and ND: YAG laser protection, fiber optics

Standard: CE EN207

Laser protection is one of the most easy to ignore but very important part, for the operator to use for a long time, if the protection is not good will cause permanent vision loss astigmatism and other serious eye problems (this is mainly due to the operation of light leakage and reflection, but not strong, the user is not easy to pay attention to), due to the high price of laser protection glasses, but the treatment itself is not beneficial, other manufacturers will use ordinary colored plastic instead, this reflective (regular should use absorbent material) without any coating plastic, there is no protection at all, or the use of absorption level is too low (at least in OD4 + above to have effect) and without any relevant certification products impersonation; currently we use TR90 environmentally friendly durable frame + PC lens + imported special absorbent material coating, product certification is the German formal testing The product certification is issued by the German formal testing agency, the implementation of the standard: CE EN207, can provide reports and certification, the highest level of protection up to OD7 +.

The following are our products in kind: all-black models, you can wear myopic glasses at the same time, the most popular one.

The following are other manufacturers equipped with laser protective glasses: can not issue the certificate of the certification body of the European mainland, are domestic testing agencies, do not have the authority, CE standards are not the same, the absorption rate is lower than OD4, some products are also parameters are also written blindly, such no certification body recognized products do not have any protection.

2. Silicone protective eye shields

The use of more soft and comfortable silicone eye shields, generally hard plastic eye shields low price to bring up uncomfortable, there are also more high-end metal eye shields, this need to order separately.

The following are high-end metal eye shields

Summary

Laser power problem

The size of the power depends on the real effective power, currently misrepresented (such as the input power of the laser or the power of the laser power supply, but in fact only the output power of the laser is the effective power), and reduced power (for example, originally 600w but according to 450w to use, which can solve the problem of the short life of the laser) use of many cases;

The problem of spot size

Generally like to report this data large, because customers feel that the larger the spot treatment area, the higher the efficiency, which is true, but at the same time the larger the spot, the lower the energy density.

Power, pulse width, and frequency calculation problems

Total power multiplied by pulse width (laser action time) equals total energy, total energy divided by spot area equals energy density, low energy density directly affects hair removal effect, frequency, and the maximum duty cycle is relative, the general laser maximum duty cycle is 10 to 20% (the better the laser duty cycle is higher, for example, microchannel can be up to 40%, fiber laser can be up to 60%, so these two lasers are very expensive) In order to 20% duty cycle laser for example: 600w * 0.02s (10hz) = 12J, 12J / 1cm2 = 12J/cm2, 10Hz maximum pulse width can only be used to 20ms, 1Hz case can be used to 200ms, the current 10 ~ 15J/cm2, 10Hz parameters are the best effect, in short, to see a laser performance parameters, the main Is to look at the total power, 10Hz maximum duty cycle (can be understood as the laser working time, the faster the luminous frequency laser working time is shorter) can be.

Spot area

Currently, we are designed to 600w ~ 1200w using 1 ~ 1.2cm2 spot area, 1200w ~ 1800w using 2cm2 spot area (low-end greater than 2cm2 spot will generally use 500w/600w laser and our effect is 2 ~ 3 times worse, 1cm2 spot with 150w ~ 300w this can also remove hair but the power is too low, too (The action time is usually lengthened to 100ms = 0.1s or so, so it will be very painful, the laser life is also low), the spot size can also be said that the window piece (light cone in front of a window piece, the final is the window piece contact with the human body) area, because it will be larger, for example, 10 * 12 light cone, the window piece should be 12 * 14.

Thermal relaxation time

Hair follicle melanin absorption of laser energy, resulting in hair follicle necrosis, because the hair follicle does not have nerve endings will not have pain, but the skin has a thermal relaxation time, simply put, is a time between the cells to transfer heat, usually about 30ms, the laser energy action time is greater than this time, the heat will be conducted to other normal cells with nerve endings, the pain began to produce, the longer the pain intensified, according to the Formula can be seen, if the need for energy remains unchanged, the greater the power of the laser, the smaller the pulse width required, for example, 1000w laser only 10ms (10hz), you can do 10J, almost no pain, while for people with dark skin pain greatly reduced, on the contrary, low power lasers, you need to increase the pulse width (this pulse width increase is also dependent on the conditions of use of the laser, for example 300w 20% duty cycle of the laser, 300w * 20ms (10Hz) = 6J effect is much worse), the pain is increased.

Process part

Many small factories simply have no process and can glow aging a few hours even if the qualified products, the production environment is also relatively poor, this is mainly to reduce costs, but the product basically does not have any quality assurance.

At present, our own production system is according to ISO13485: 2016 medical system production (being certified, not the kind of money can buy), from product design to raw material procurement, production, quality control, shipping, and so on a series of processes are strict requirements.

Take the handle assembly process as an example

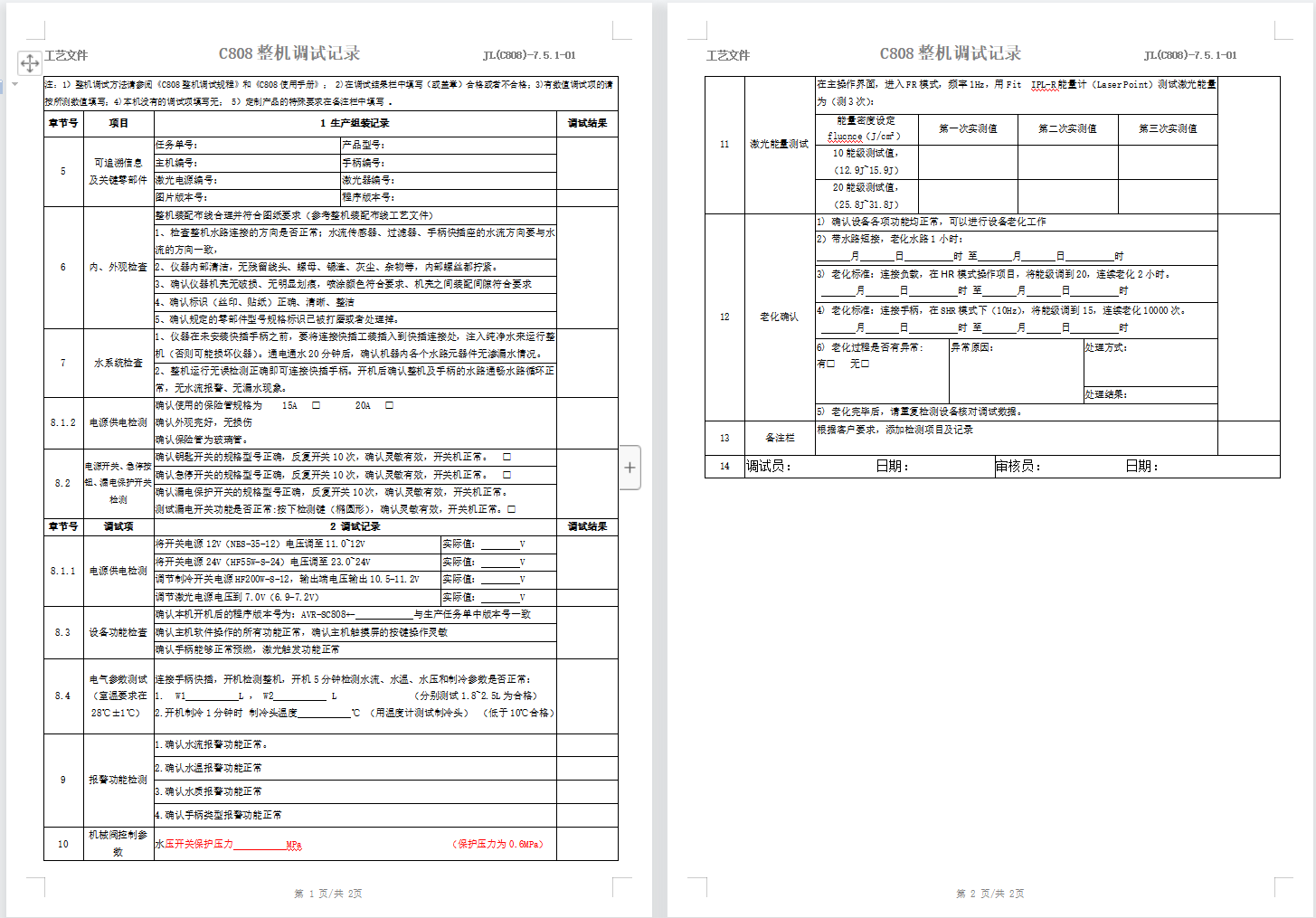

Product commissioning records

Our company's semiconductor production environment

VS

Video screenshots of other manufacturers' production environment

FAQ

1.600w and 1200w difference, as well as the treatment time and treatment results?

1.1 Clinical effect: the higher the power, the higher the power density under the same spot area, and the better the effect of hair removal, hair removal is also more comfortable, at the same time for dark skin color customers also applicable, 600w usually the clinical effect is not very obvious, dark skin pain is strong, 1200w usually after 2-3 times scanning operation, there will be red mounds around the hair follicles raised, proving that the hair follicles have been seriously damaged, dark skin Skin can be used 5-10ms ultra-short pulse width (the shorter the time the lower the pain) mode to carry out, the pain is greatly reduced, 600w can usually only do a Min of 20-30ms is 2-3 times the pain of 1200w.

1.2 Treatment cycle: 1200w is usually 2-3 times and can complete more than 95% of the hair removal, 600w usually needs 5-6 times to complete more than 80% of the hair removal, and hair removal is usually treated once a month.

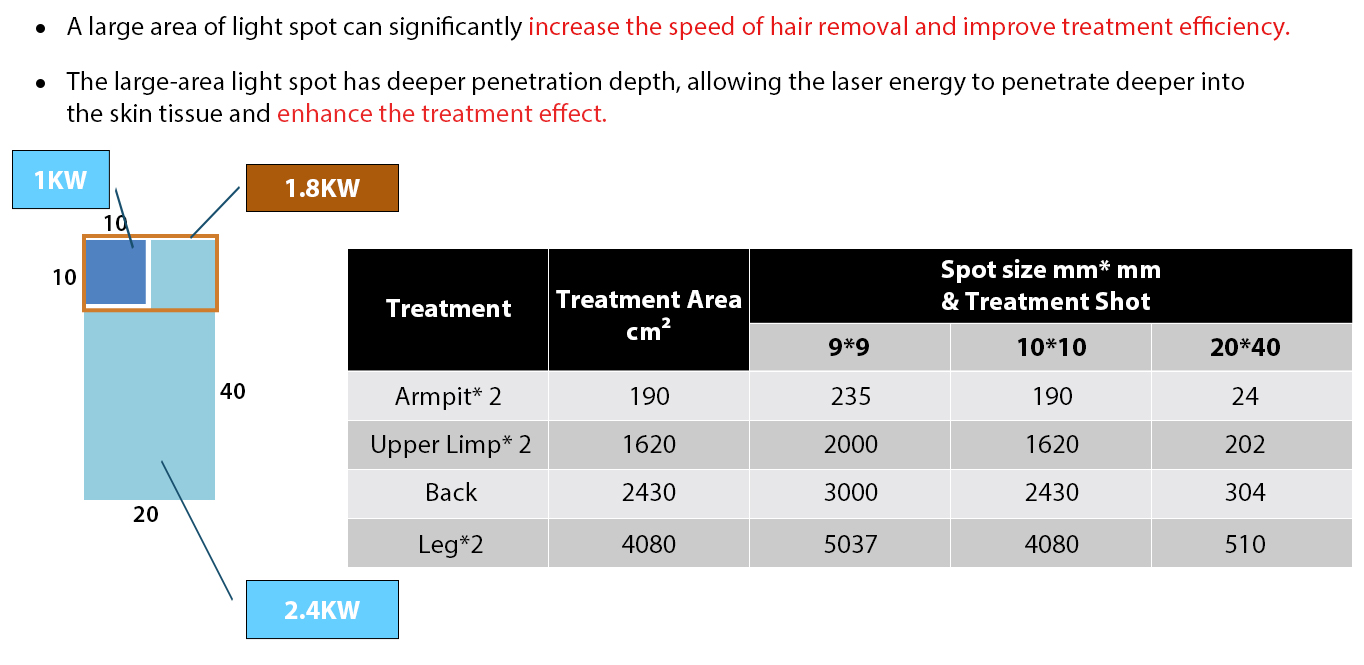

1.3 treatment efficiency: greater power can also do a larger spot to improve the single treatment time (spot size determines the treatment efficiency, power, and spot determine the power density = energy density determines the treatment effect), the current 600w is only suitable for 10 * 10mm or 10 * 12mm spot size, the treatment efficiency is general, but the treatment effect can be, the same spot size 1200w best, the effect Also more than 3 times the effect of 600w, currently more popular large spot usually then 10 * 20mm or 10 * 25mm, large spot to ensure that to achieve better efficiency and effect at least 1200-1800w laser, the current market to 500w (10 bar actual single bar 50w, falsely claimed single bar 100w, propaganda 1000w laser) with a large spot mostly The price is low, the disadvantage is that the effect is poor, suitable for the low-end market.

2. What are the advantages of a large spot? How to match the laser power?

At present, according to the international standard, a 10*10mm spot area at least with a 1000w laser, 10*20 with a 1800w laser is the best, and a 2400w laser is suitable for adsorption hair removal.

3. How many points can the instrument play?

Currently, on the market the number of points is mostly 2000W, 5000W points, and other descriptions, fiber 808 and micro-channel 808 general points will say more, it should be noted that this is not a warranty point, such as to less than 2000w points are bad, free replacement or repair, this belongs to the warranty point, no matter how long you use not to points are bad belong to the warranty; but the vast majority of manufacturers are actually warranty by time. That is, the warranty period to go to the warranty points, this current policy of our handle warranty 2 years of unlimited points, due to the general customer use points a year is usually about 500w points, more than 1000w (special need to use a lot of very knowledgeable will use foreign instruments or domestic high-end micro-channel and other expensive instruments, such instruments due to the high selling price by point warranty is also no problem is usually 2000w, customers can basically 1-2 years to consume light), there are some small beauty salons are also two or three million points of use, completely then the warranty period can say more points.

There are some cheap lasers that will also warranty for a long time or points said a lot, this situation is generally the actual power with very low, such as the use of lasers in accordance with 70% efficiency, so as to effectively extend the life of the laser, but will sacrifice the effect, lengthening the treatment cycle, for some fine hair caused by the inability to take off, etc., according to some of our actual test, most of the actual energy is only about 60% of the nominal energy According to some of our actual tests, most of the actual energy is only about 60% of the nominal energy, and this kind of customers can not be identified without professional equipment.

To sum up: no more false table energy parameters, to achieve stable energy output and long service life, is fundamental, otherwise the same hair removal area, low energy needs 2-3w points, 5-6 cycles or longer to see results, but can guarantee 2000w, and high energy only need less than 1w points, 2-3 cycles can reach 95% hair removal effect, guarantee points 1000w, choose that kind of need not more Say, so then consider the hair removal effect and efficiency (higher requirements will consider the comfort especially dark skin this point more high-power lasers occupy the advantage) under the premise, then focus on the expected life.

4. About macro channel, microchannel, no channel

The so-called channel refers to the laser's internal heat dissipation waterway, the better the heat dissipation effect of the laser can use the greater the power. Micro-channel heat dissipation is more full but the waterway is very small and easy to block, the macro-channel waterway is very large but the general effect of heat dissipation energy can not be used too high, no channel is not in the laser internal heat dissipation, but still need the waterway heat dissipation.

Mastering HIFU: Step-by-Step Operating Guide and Real-Life Demonstrations

Mastering HIFU: Step-by-Step Operating Guide and Real-Life Demonstrations

Understanding the Differences Between Picospeak 300 and 500 in One Article

Understanding the Differences Between Picospeak 300 and 500 in One Article

Russian Agents Experience Warm Welcome and Cutting-Edge Beauty Instrument Exports at SEA HEART GROUP

Russian Agents Experience Warm Welcome and Cutting-Edge Beauty Instrument Exports at SEA HEART GROUP